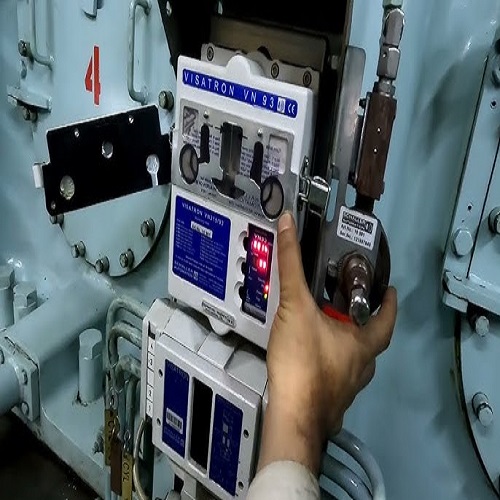

Oil mist Detector Calibration Service Details:

Functional Testing: Verifying that all parts of the

system are working as intended, including the sensors, alarm panel, and any

associated relays or shutdown mechanisms.

Accuracy Verification: Testing the detector's ability

to accurately measure oil mist concentration. This is often done by generating

a known concentration of oil mist (in mg/L) and comparing the detector's

reading to this known value.

Alarm Set Point Verification: Ensuring that the alarm

is triggered at the correct pre-set levels. The alarm set point is typically a

low percentage of the Lower Explosive Limit (LEL) for oil mist.

Time Delay Measurement: For systems that draw mist

through piping, the service will measure the time it takes for the alarm to

activate after the mist is detected at the source.

Cleaning and Maintenance: Technicians will clean the

sensor heads and other components to remove any oil film or dirt that could

interfere with the detector's function. They may also replace O-rings or other

worn parts.

Certification and Documentation: After a successful

calibration, a certificate is issued to prove the system meets industry

standards and regulatory requirements. This document is crucial for compliance.